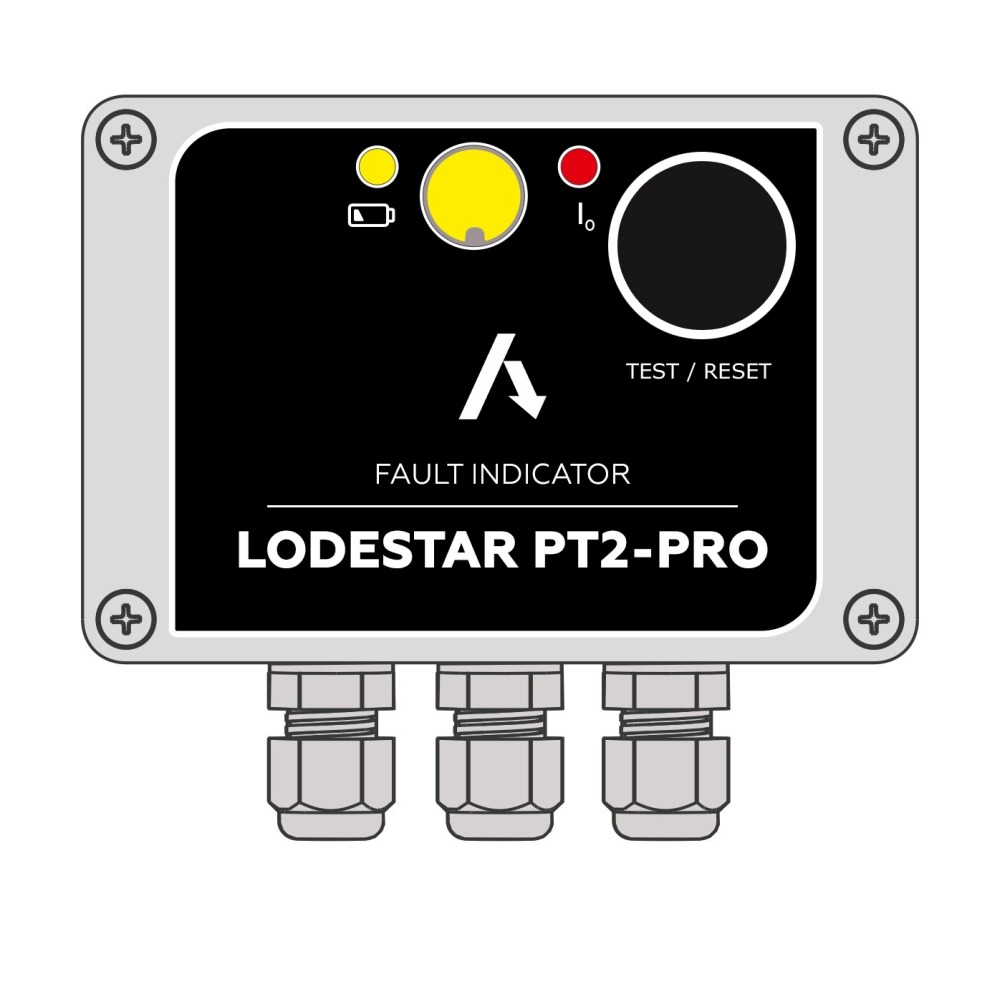

Lodestar PT2-PRO

Cable fault indicator Lodestar PT2-PRO Technical characteristics

| PARAMETER | VALUE |

| Events | |

| Types of registered faults | PtG |

| Current response threshold PtGn | 10 A |

| General description of the Device | |

| Operating voltage | 6-35 kV |

| Indication |

- High Intensity LED; - Mechanical Blinker; - External signal LED. |

| Power supply |

- Main power supply of the device – 110/230 VAC, 120-220 VDC; - Backup power supply (lithium battery) for fault indication in case of main power failure (LED blinking time not less than 1200 hours). |

| Reset the fault indication |

- By external command by closing the dry con-tacts; - By timer; - Button on the device. |

| Trigger control |

- Visual; - According to MODBUS protocols (if there is main power supply); - Relay output. |

| Mean time between failures | not less than 110 000 hours |

| Additional features | changing of setpoints by DIP switch |

| Parameters | |

| Zero sequence current threshold range | 10 ÷ 200 A with a step of 10 A, 0 - all settings are configured via MODBUS |

| Indication/fault reset time | 1; 2; 4; 8; 16; 36 hours, 0 - indication reset off |

| Indication/fault reset time after ap-pearance of the power | 10; 30 seconds, 0 - indication reset off |

| Time Analyze PtG | 80; 160 ms, 0 - delay off |

| Design | |

| Installation | On the control panel in the switchgear and control gear cell / Wall-mounted |

| Sensors | own zero sequence current sensor |

| Temperature range | standard from -40° C to +70° C |

| Device protection degrees | IP 65 |

| Sensor protection degrees | IP 67 |

| Impact of external climatic factors | S4 design group according to the requirements and Moderately Cold Climate design of placement category 3.1 according to IEC 721-2-1, but for operation at ambient air temperature from -40 to +70°C |

| Impact of mechanical factors | M7 design according to IEC 721-3-3-87, design group N2 according to the requirements |

Lodestar PT2-PRO is designed to detect a damaged section on overhead lines and cable lines of power distribution networks of 6-35 kV. Device can operate on lines with insulated and resistive neutral points. Device is placed in the substation, wall mounted.

The device is triggered and the fault is registered during single-phase earth faults in the monitored line, accompanied by a sudden increase of cur-rent in the damaged phases, depending on the settings made by the user.

The device can register non-directional PtG faults by measuring only the zero sequence current using its own current sensor.

The device has a digital interface for setting using special software and data transfer to SCADA - RS-485 (not galvanically isolated, MODBUS protocol) when operating from the main power supply.

The device supports self-updating via RS-485 using special soft-ware.

Cable fault locator Lodestar PT2-PRO benefits:

- Phase-to-Ground faults detection;

- Fault indication by switching on ultra-bright LED and mechanical flag;

- Main power supply of the device – 110/230 VAC, 120-220 VDC;

- Standby Lithium battery for backup supply of LEDs emergency indication while loss of main power;

- Digital interface to SCADA - RS-485;

- Low battery level indication.

Current sensor of Lodestar PT2-PRO is installed on the cable's armor of three phases. Indicator is installed on the control panel in the switchgear and control gear cell.

Lodestar PT2

Lodestar PT2 Lodestar PT1

Lodestar PT1 Lodestar PT3

Lodestar PT3