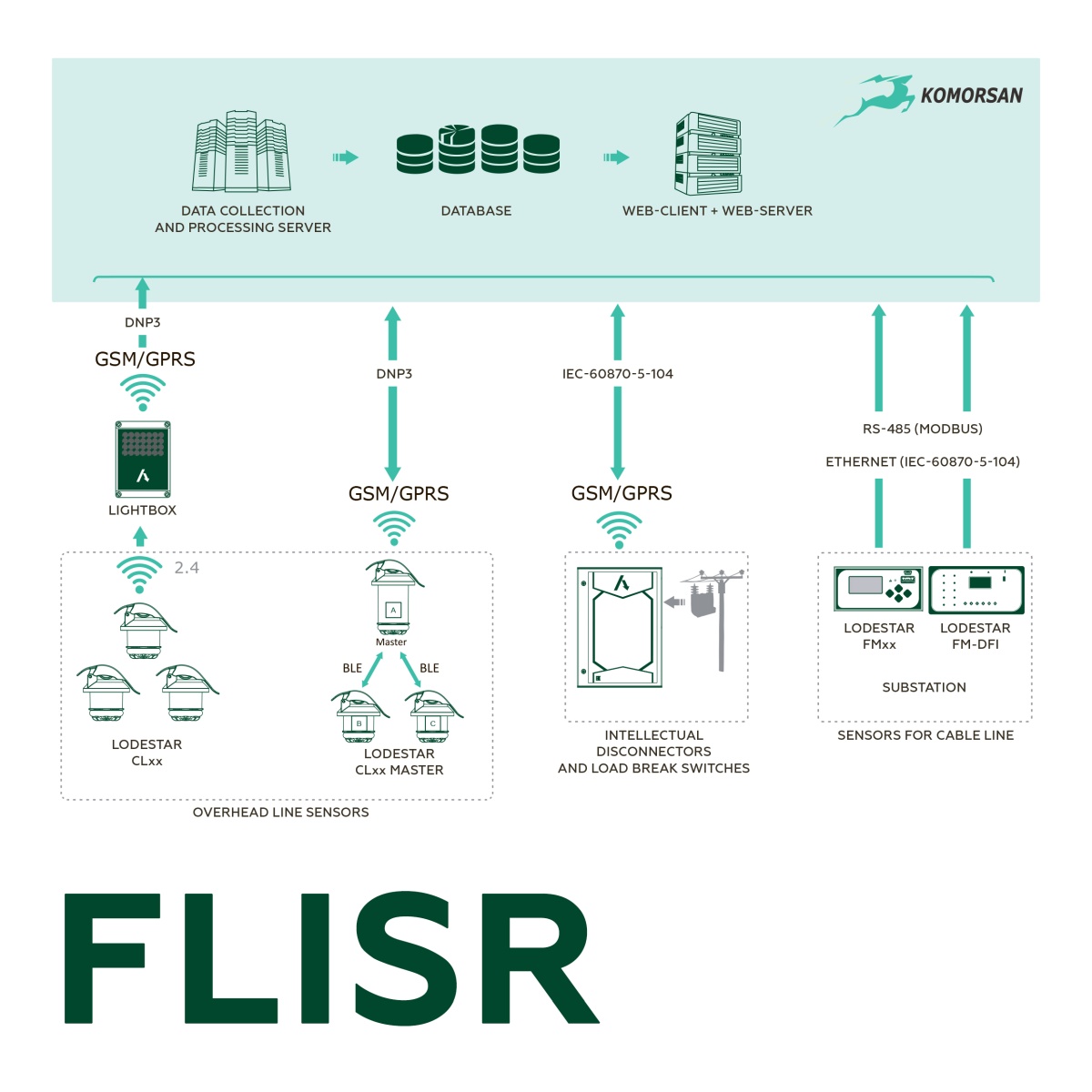

FLISR software and hardware complex

| PARAMETER | VALUE |

| Voltage class of overhead and cable lines | 6-35, 110 кV |

| Type of recorded faults |

- Identification and determination of the direction to the place of 2 -and 3-phase-to-Phase Faults; 2- and 3-phase Phase-to-ground faults; - Identification and determination of the directions of Phase-to-phase faults. |

| Minimum emergency current | 0.5 А |

| Selectivity | Determination of type and direction of fault |

| Ways of information processing |

- via Bluetooth Channel; |

| Registration | - Voltage; - Current; - Power; - Industrial frequency; - Capacity coefficient acc to three phases; - Flow distribution direction; - Overflow values. |

| Temperature range | from – 40°С to + 85°С |

Designed for the implementation of FLISR (Fault Location, Isolation and Supply Restoration) technology in 6-110 kV distribution network - determining the location of damage on overhead or cable power line and partitioning the damaged section to restore power supply to serviceable sections of the network, including:

- Identification of the damaged area.

- Separation of the damaged section of network.

- Restoration of power supply to serviceable sections of the network.

- Return to normal state of the network (after the damage has been repaired).

Effective use of FLISR Software and Hardware Complex:

- Cable (urban) networks with fully controlled switching devices in RM-6 units;

- On overhead lines with two-way power supply, in case of damage requiring the transfer of the point of normal current separation;

- Partitioning of long overhead lines by means of several disconnectors.

Activation of algorithm for separating the damaged area in FLISR Software and Hardware Complex is carried out with control of the command delivery time and prohibits other switching at SCADA level. The system controls the process of execution and successful completion of the separation algorithm, records changes in the position of the switching device, the presence of voltage, current surges, and so on. After restoring power due to the fact of damage repair, FLISR module of the monitoring and control system checks the absence of overloads on overhead line.

FLISR algorithm is implemented in a large non-current pause of Software and Hardware Complex cycle, used on a switch in the power center or on a recloser installed on the main section of overhead line. Such solution has the following advantages:

- minimum power timeout for consumers located in undamaged areas;

- minimum of switching devices involved (no retrofitting of reclosers or switches in the power center for information transmission and remote control is required);

- all operations are carried out in automatic mode (except restoring normal power supply scheme – it is carried out in semi-automatic mode).

FLISR Hardware depends on the topology and the existing equipment in the controlled area. Features of FLISR Software and Hardware Complex :

- Work in networks with any type of neutral.

- Work in networks of any topology with one-way and two-way power supply.

- Work on overhead, cable and overhead cable lines.

- Monitoring and management of overhead transmission line nodes by equipping with remotely controlled disconnectors and short circuit indicators with information transmission to SCADA system.

- Observability of each transformer and distribution substation due to the equipment of feeder monitors.

- A scalable system with an increase in both hardware and functional components.

FLISR Software and Hardware Complex consists of a complex of wire-mounted Fault Passage Indicators for overhead line, Pole-mounted overhead line disconnectors and switches, and electrical network monitors installed in control panel cells. All devices measure the parameters of the lines and transfer information to the system server and to the dispatch center via GSM or Protocol. When processing information from Indicators (FPIs), the algorithm of determining the location of the damage is implemented and a command to turn off the damaged area is issued.

Analytical part of system consists of modules for displaying the devices included in the system and their analyzing on the geographical map and mnemonic circuit of the network, determining the damaged area and the accident site on the mnemonic circuit, and partitioning options.

Intelligent disconnector IDD

Intelligent disconnector IDD Load Break Switch IDD-CB

Load Break Switch IDD-CB Monitoring and control system KOMORSAN 2

Monitoring and control system KOMORSAN 2 Lodestar CL0.5B

Lodestar CL0.5B Lodestar CL0.5 BM

Lodestar CL0.5 BM